Production is a specialized system developed by Soluciones Puntuales en Informática, designed to modernize and monitor each phase of the tire retreading process in Colombia.

The tool allows you to control the flow from the moment the tire arrives until it is delivered to the customer, view a detailed record of each tire and its owner, manage rejections during production, and issue dynamic, updated reports instantly.

Records and controls each tire from its arrival to final delivery, ensuring traceability throughout the retreading process.

It oversees each phase of production, ensuring that the same tire that enters the factory is the same one that leaves the factory retreaded, with clear and auditable status changes.

Manage tire rejections at any stage of production, documenting the causes and maintaining a transparent history for quality control.

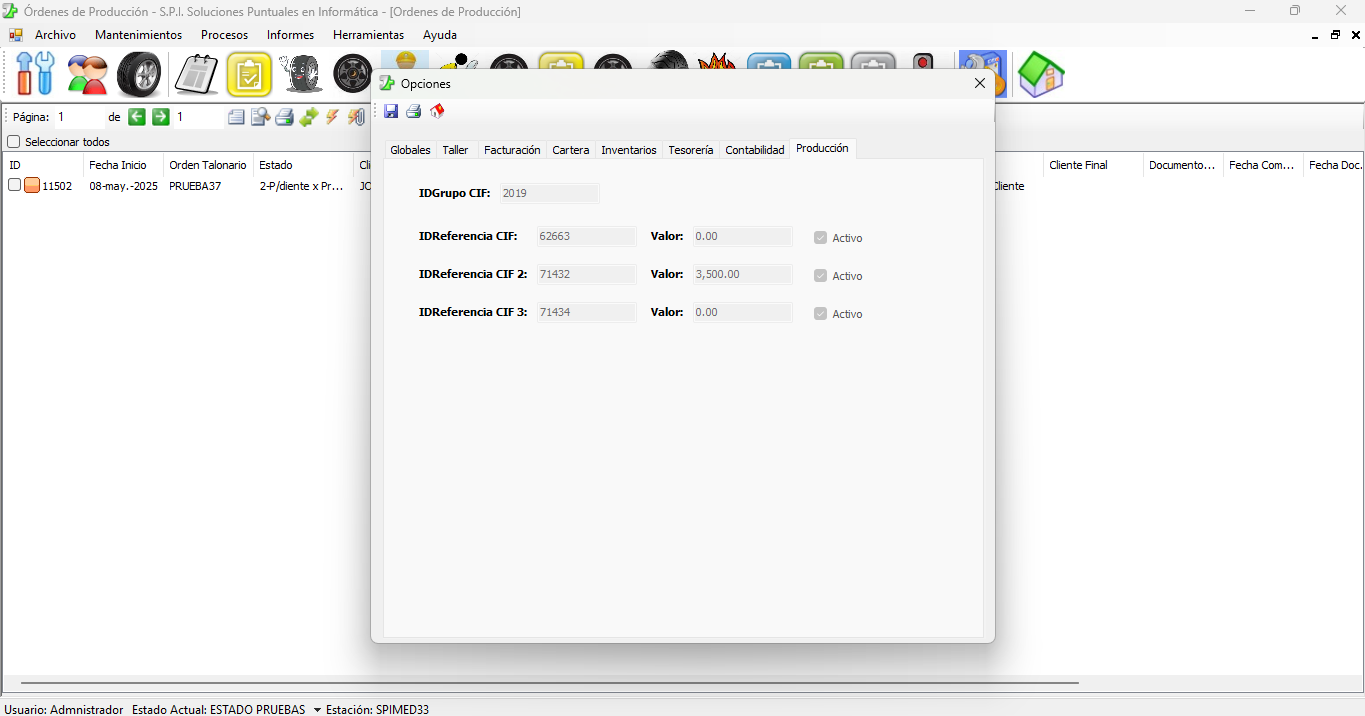

Automates the calculation of indirect manufacturing costs (CIF) for each tire, ensuring detailed financial control of the operation.

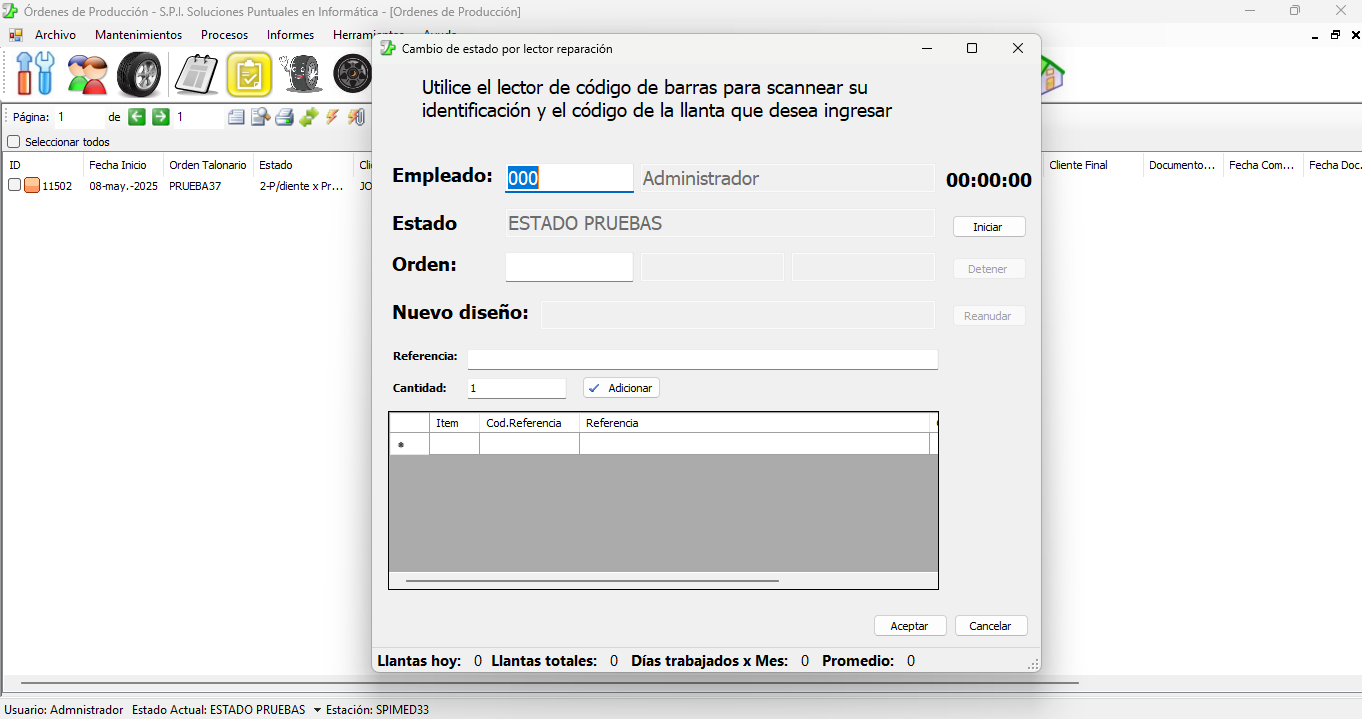

Schedule production orders, associate responsible users, and monitor their progress with barcode scanning to streamline status changes.

Manage tire, material, and spare parts inventories, linking warehouses and references to maintain accurate stock control.

If your company needs a reliable tool to manage and optimize the tire retreading process, SPI Production is the ideal option. With this platform, you can maintain complete tracking of every phase, from tire reception to final delivery, with immediate access to historical records, quality control, costs, and strategic reports in a single system.

Adding indirect manufacturing costs (IMC) to a production order allows for a more accurate calculation of the true value of each product produced. By considering expenses such as energy, maintenance, or machinery depreciation, a comprehensive cost is obtained that accurately reflects the production process.

This information directly impacts Inventories, since finished items record a more accurate value, avoiding distortions in accounting and ensuring reliable cost management

In tire retreading, every detail makes a difference. That's why we developed retreading software that transforms the way we work in the plant: it allows you to monitor each tire throughout its production run, control inventories, and generate valuable reports for decision-making.

The reader-based status change feature allows you to quickly update the status of a ticket or production order using a barcode reader. By simply scanning the assigned code, the system automatically identifies the record and applies the transition to the new status defined in the workflow.

This tool reduces manual errors, streamlines process traceability, and improves control in the plant or support areas.

We know that choosing a management system is an important decision. That's why SPI Production offers you a trial version that will allow you to explore its features directly in the tire retreading process.

SPI Production is not just a computer system: it's a solution designed to meet the work pace and real-world demands of each retreading plant in Colombia. The platform adapts to your processes and allows you to maintain complete control, from tire reception to final delivery.

Learn how Production transforms the management of the production process at retreading plants.

Yes. In addition to Production, we develop solutions such as SPI CRM, focused on business sales management, and SPI Workshop, a software specialized in the administration of motorcycle, automobile, and machinery workshops. We also have an ERP system that allows for integrated administrative and accounting processes, and Ensambladoras, a platform focused on the control and management of motorcycle assembly. Each solution is designed to meet the specific needs of the Colombian market, facilitating the operation and growth of your business.

Conoce más: